Lubricant drop-in replacement is defined as the substitution of existing fluid in a system with RSC Bio HEPR type lubricants with minimal flush-out and no substantive changes to hardware such as seals or gaskets required to successfully use FUTERRA™ or ENVIROLOGIC® HEPR for at least one comparable dry dock cycle and no negative impact on performance or lifetime of seals or gaskets following changeover.

Stability and compatibility are the keys to creating fluids that are true drop-in replacements for either mineral oil or other EAL technologies.

Key characteristics of stability:

• Viscosity and shear resistance.

• Compatibility with other lubricants.

• Resistance to oxidation which causes discoloration, sludge formation and in severe cases viscosity loss.

• Resistance to hydrolysis which causes decomposition, viscosity loss and decreased lubricity.

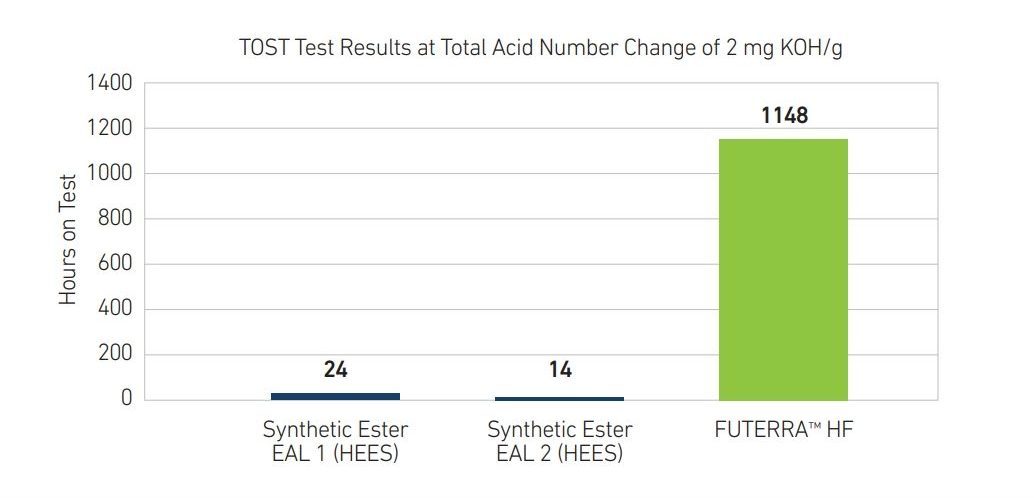

In a standard ASTM D943 oxidation test, FUTERRA™ hydraulic fluid easily surpasses competitor EALs showing excellent stability under the worst conditions of heat and moisture.

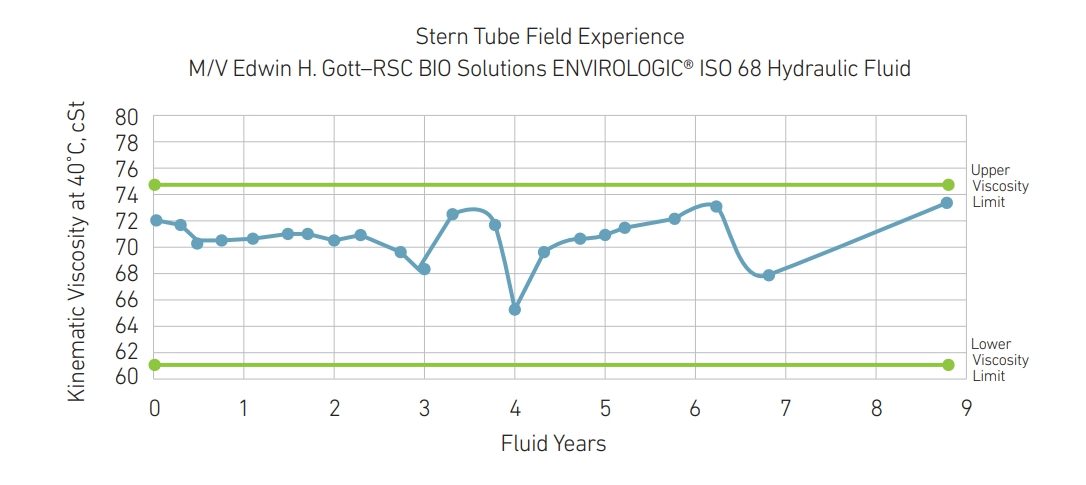

More than a decade of oil analysis from stern tube applications demonstrates the ability of our HEPR fluids to maintain lubricating stability well beyond a 5- year dry docking cycle. This chart shows stable viscosity for nearly seven years in the stern tube of the M/V Edwin H. Gott.

STABILITY In service oil analyses demonstrate FUTERRA™ and ENVIROLOGIC® HEPR EAL stability is better than the fluid it replaces:

• Hydrolytic stability – FUTERRA™ and ENVIROLOGIC® HEPR EALs provide lower to no acid formulation compared to incumbent fluid. Proven by both laboratory testing (ASTM wet TOST) and ongoing oil analyses (for total acid number, TAN) from vessels in service. RSC Bio HEPR lubricant products meet the most stringent requirements for EALs as listed in International Standard ISO 15380:2016. In many cases, the stability of RSC Bio HEPR EALs are as high, if not higher than, conventional mineral oil based non-EALs.

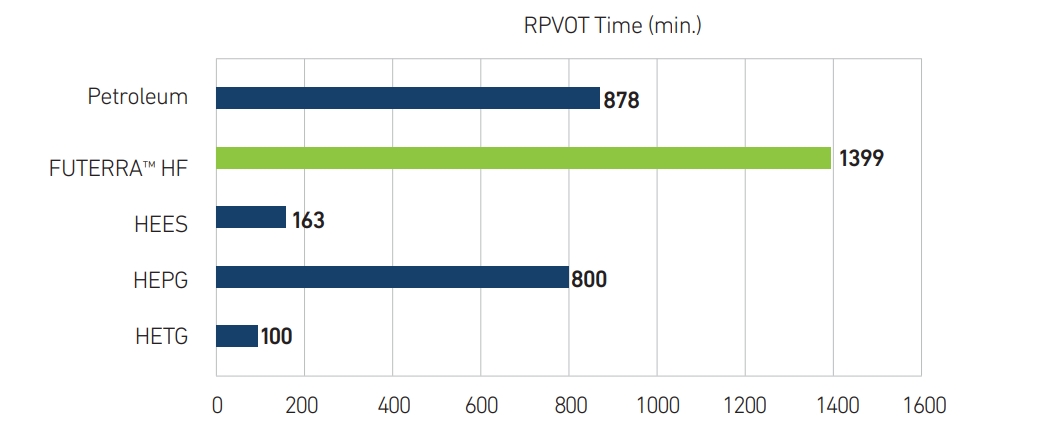

• Oxidative stability – FUTERRA™ and ENVIROLOGIC® HEPR lubricants provide higher resistance to oxidation when compared to incumbent fluids. Ongoing oil analyses of fluid in service demonstrate the stability of FUTERRA™ and ENVIROLOGIC® HEPR fluids for both stern tube and thruster applications as does laboratory testing using the ASTM RPVOT test

method for determination of oxidative stability of oils.

• Viscosity stability – RSC Bio HEPR EAL viscosity is stable between dry docks. This is demonstrated by case studies of ongoing oil analyses.

In this standardized oxidation test, ASTM D2272, FUTERRA surpasses not only the stability of competitive EALs but also an industry-standard mineral oil based hydraulic fluid. This is further proof of the long-term performance of FUTERRA™ hydraulic fluids.

Few, if any, EAL providers can demonstrate the hydrolytic, oxidative stability and fluid, seal compatibility that RSC Bio can. Our HEPR type technologies mean that in many ways our lubricants behave like the mineral oils they replace.

COMPATIBILITY In service oil analyses demonstrate FUTERRA™ and ENVIROLOGIC® compatibility is better than the fluid it replaces:

• Compatibility of RSC Bio HEPR with other fluids has been frequently demonstrated in field conversions from other EALs and petroleum based lubricants and follow-up ongoing oil analyses that consistently show no incompatibility with the fluids that FUTERRA™ and ENVIROLOGIC® replace.

• The only exception for RSC Bio HEPR type EAL compatibility is polyalkylene glycol (PAG) EAL technologies that are incompatible with ALL other fluid types because of the base oil type used to formulate PAGs.

• Conversion from PAG to RSC Bio HEPR EALs or from PAG to any other fluid requires a complete tear down and cleaning of the system prior to installation of a non-PAG fluid, regardless of manufacturer.

RSC’s RECOMMENDATION FOR CUSTOMERS

Not all EALs are the same. It’s important to understand the differences in performance measurements, results, and implications.

SEAL PERFORMANCE Compatibility of FUTERRA™ and ENVIROLOGIC® with seal materials has been demonstrated by compliance of RSC Bio HEPR EALs with the seal performance requirements of the ISO 15380:2016 standard for HEPR base oil types (the most stringent requirements within ISO 15380) as well as multiple OEM approvals of FUTERRA™ and ENVIROLOGIC® HEPR EALs for use with NBR, HNBR, and FKM seals.

• Seal compatibility is ensured by testing against the stated standards for volume change, hardness, tensile strength, and elongation in third-party ISO 6072

• FUTERRA™ and ENVIROLOGIC® HEPR EALs are compatible with sealing materials in thruster, stern tube, and CPP applications as demonstrated by multiple OEM approvals that rely on both static laboratory tests as well as dynamic testing in test rigs designed to mimic worst case conditions aboard