View the complete article here.

Preface

Performing maintenance work underneath the dump body of a dump truck presents extraordinary hazards to maintenance or servicing personnel. During an OSHA inspection at a heavy construction equipment maintenance shop, an employee was observed working between the elevated 4,000 pound dump body and the truck’s frame. The employee could not utilize the truck’s original “body prop” to support the dump body since the “body prop” would not position the dump body high enough for the employee to access the back of the truck. Consequently, employees place themselves under the elevated dump bed without proper protection.

A citation was issued for failing to provide lockout procedures while employees were working under the dump body and for failing to isolate and sufficiently block the dump body prior to doing work under the dump body. As a result, the employer contacted the University of Wisconsin-Madison Structures and Materials Testing Laboratory to develop truck bed brace brackets that would support loads over 47,000 lbs. This represented a significant engineering challenge and the positive outcome that resulted should be shared with other employers.

Purpose

The purpose of this Safety and Health Information Bulletin (SHIB) is to:

- Alert employers and employees who service or maintain dump trucks or haulage trucks about the hazard of falling dump truck beds;

- Remind employers that in construction settings, 29 CFR 1926.600 (a)(3)(i) requires that dump bodies shall be fully lowered or blocked when being repaired or when not in use;

- 29 CFR 1926.601(b)(10) also requires that in construction settings, trucks with dump bodies shall be equipped with positive means of support, permanently attached, and capable of being locked in position to prevent accidental lowering of the body while maintenance or inspection work is being done; and

- Detail actions to prevent unintended falling of the dump truck bed, which include implementing components of a lockout/tagout program.

Background

The Occupational Safety and Health Administration (OSHA) reviewed its Integrated Management Information System (IMIS) accident data, and identified 31 accidents during the past 10 years that involved the unanticipated release or movement of an elevated truck bed. Nearly all of the accidents resulted in fatalities. OSHA urges employers whose employees service or maintain dump trucks to implement an effective Lockout/Tagout Program in general industry settings or to implement the above referenced construction standards in construction settings to prevent unintended releases or movement of the truck beds which can result in a employee’s death or serious injuries.

The Occupational Safety and Health Administration (OSHA) reviewed its Integrated Management Information System (IMIS) accident data, and identified 31 accidents during the past 10 years that involved the unanticipated release or movement of an elevated truck bed. Nearly all of the accidents resulted in fatalities. OSHA urges employers whose employees service or maintain dump trucks to implement an effective Lockout/Tagout Program in general industry settings or to implement the above referenced construction standards in construction settings to prevent unintended releases or movement of the truck beds which can result in a employee’s death or serious injuries.

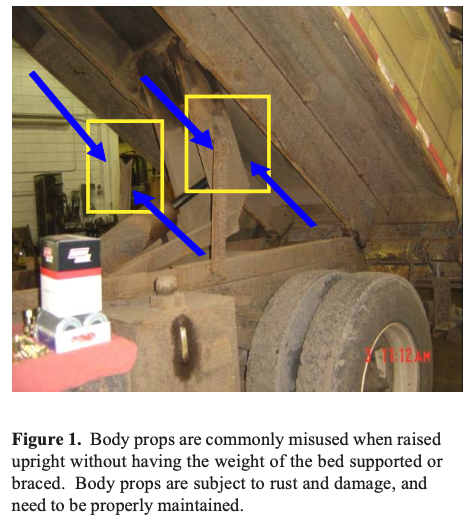

Typically, employee exposures occurred during routine maintenance or during troubleshooting activities. Work performed under the raised beds involved repairs to air or hydraulic lines, framework welding, electrical wires and release cables, power take-off shafts, hydraulic pumps, fuel pumps, and routine greasing. Body props were not used, or were used improperly, in a majority of the accidents. In a few cases, the props were used but they failed. Causes for the sudden movement of the dump bodies included: inadvertent control operation, inadvertently pulling a release cable, hydraulic failure, and premature reconnecting of an air line.

The following three sample OSHA cases illustrate some of the problems faced when using non- engineered dump body props. (Ref: OSHA IMIS).

The following three sample OSHA cases illustrate some of the problems faced when using non- engineered dump body props. (Ref: OSHA IMIS).

- Example 1: An employee was replacing the rear stabilizer bar on a tandem dump truck. The dump bed was raised and the safety support was in place. At some point, the lift hydraulics for the dump bed failed, allowing the weight of the bed to rest on the safety support bracket which also failed, causing the bed to come down and crush the employee.

- Example 2: Two employees were installing a dump bed onto a dump truck. The dump bed was being raised up and down by slings attached to a bridge crane. The dump bed had been raised and lowered several times to make sure that the bed was aligned on the truck chassis correctly. The back of the dump bed was bolted in place. The dump bed was then raised one more time so that a tubular rod could be placed under the bed to hold it in the upright position while one employee worked under the raised bed. While placing the tubular rod under the dump bed, the safety latch on the crane hook failed. This allowed the slings to come off the hook. The dump bed pinned both of the employee’s arms under the bed between the chassis and the dump bed.

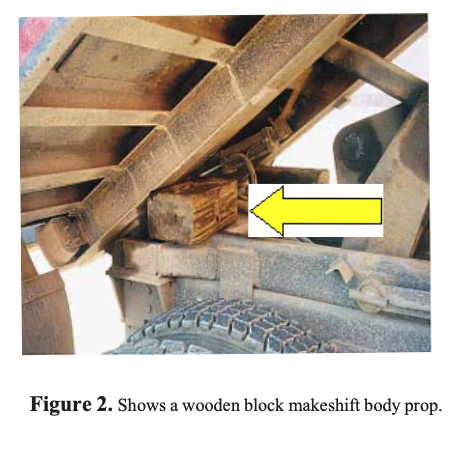

- Example 3: An employee was greasing the U-joints on a 1970 Mack dump truck. He had raised the dump bed and had propped it up with a 4’’by 6’’by 8’ piece of wood. The wood dislodged and the bed came down onto his back, pinning and seriously injuring him. The employee later died.

One reason that the props provided by the truck body manufacturers are not used, or are not used appropriately, is that when raised to the typical body prop height, there may not be sufficient accessible space to perform the needed maintenance.

One reason that the props provided by the truck body manufacturers are not used, or are not used appropriately, is that when raised to the typical body prop height, there may not be sufficient accessible space to perform the needed maintenance.

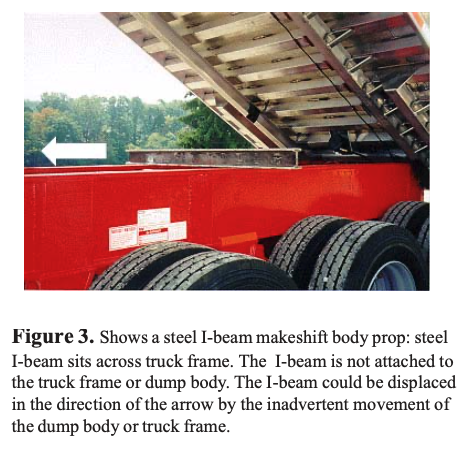

Mechanics need to access the rear of the truck where damage often occurs to air or hydraulic hoses, electrical lines, control cables and hydraulic motors. To access these areas, the truck body must be moved to a higher position than is supported by the manufacturer’s prop. In these circumstances, employers often need to provide additional bracing or support. However, if not properly designed to support the weight of the dump body, these methods can be ineffective and lead to serious accidents. Employers should therefore ensure that, before making inspections, adjustments, or repairs under dump truck bodies, strong, heavy, positive supports are used to keep the dump body from inadvertently lowering.

The supports/cribbing methods shown in Figures 2 and 3 are examples of makeshift body props that do not safely support the dump body in an elevated position. Since these makeshift devices are not designed to safely support the elevated dump body they can inadvertently slip out of the truck frame while maintenance work is performed underneath the dump body.

The supports/cribbing methods shown in Figures 2 and 3 are examples of makeshift body props that do not safely support the dump body in an elevated position. Since these makeshift devices are not designed to safely support the elevated dump body they can inadvertently slip out of the truck frame while maintenance work is performed underneath the dump body.

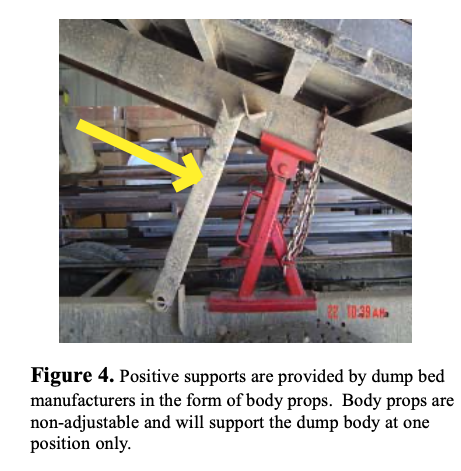

Truck Props

Strong, heavy, positive supports are provided by dump bed manufacturers in the form of body props. Body props are non-adjustable and will support the dump body at only one position that is close to the maximum elevated dump angle. Therefore, the need to inspect and/or work on the dump bed at an angle other than the one provided by the body prop will require additional or alternative protection.

Truck Bed Brace Bracket for Dump Box

As a result of the significant risk of injury or death to employees working between the frame and dump box of a dump truck, one employer developed braces to secure the dump box while employees serviced areas on the rear axles, or drive lines, and repaired the air cylinders for the tailgates that was not reachable using the manufacturer’s prop. Three tests were conducted on one prototype brace at the Structures and Materials Testing Laboratory at the University of Wisconsin – Madison using a 1-million pound test machine calibrated to National Institute of Standards and Technology (NIST) traceable standards. Loads were applied to the brackets at the rate of 10,000 lbs./min. The braces successfully passed the test.

As a result of the significant risk of injury or death to employees working between the frame and dump box of a dump truck, one employer developed braces to secure the dump box while employees serviced areas on the rear axles, or drive lines, and repaired the air cylinders for the tailgates that was not reachable using the manufacturer’s prop. Three tests were conducted on one prototype brace at the Structures and Materials Testing Laboratory at the University of Wisconsin – Madison using a 1-million pound test machine calibrated to National Institute of Standards and Technology (NIST) traceable standards. Loads were applied to the brackets at the rate of 10,000 lbs./min. The braces successfully passed the test.

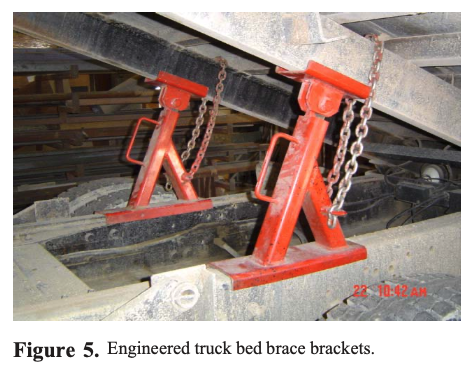

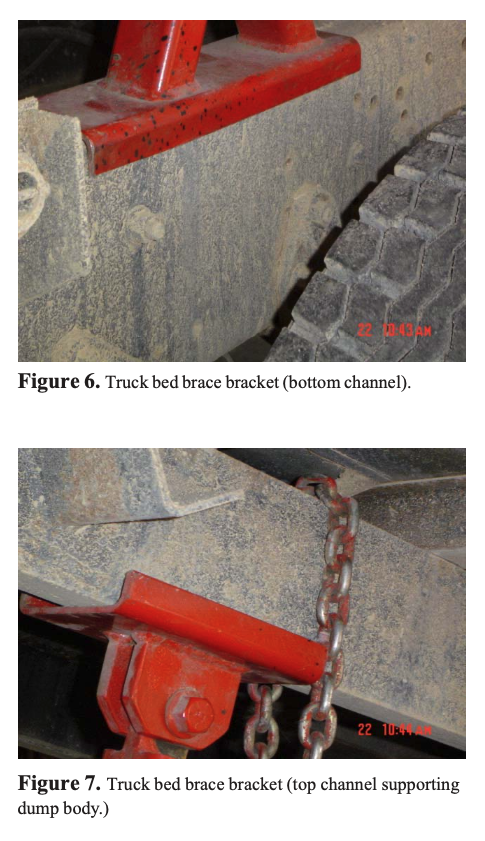

The following is an example of the prototype truck bed brace brackets (see Figures 5, 6 and 7) that were developed by the employer and can be used universally on any brand of dump box. The standard flange is 3.5 inches and the braces will fit up to a 4.5 inch channel. In addition, these braces have a handle that allows the employee to place the brace under the dump box without creating an additional hazard. The employee must rest the brace on the frame of the truck while standing next to the tires.

The following is an example of the prototype truck bed brace brackets (see Figures 5, 6 and 7) that were developed by the employer and can be used universally on any brand of dump box. The standard flange is 3.5 inches and the braces will fit up to a 4.5 inch channel. In addition, these braces have a handle that allows the employee to place the brace under the dump box without creating an additional hazard. The employee must rest the brace on the frame of the truck while standing next to the tires.

Conclusions

Manufacturers of dump trucks provide body props or braces as standard equipment but they are non- adjustable. If a higher angle is needed to access the rear of the truck, the manufacturer-provided standard prop can not be used when performing some of the service functions safely. The employer needs to specifically address the hazards of this condition and how to protect employees from these hazards. This SHIB raises awareness that the manufacturer’s standard body prop or support may not be adequate to perform certain jobs safely. The employer should determine whether the manufacturer can provide an alternative body prop that would raise the dump truck bed sufficiently to allow safe access for repairs or maintenance at the rear of the truck or otherwise ensure that the truck body is positively restrained from unexpected movement. Therefore, OSHA recommends that employers contact the manufacturer to determine if alternative body props are available, or to discuss other suitable methods to support the truck bed if the standard procedures are not possible.

The following actions can protect employees from the hazards faced when working under a raised dump truck dump body:

- Ensure that elevated parts of heavy equipment are suitably supported from unexpected movement while being serviced.OSHA’s construction standard, 29 CFR 1926.600(a)(3)(i), requires that: “heavy machinery, equipment, or parts thereof which are suspended or held aloft… shall be substantially blocked or cribbed to prevent falling or shifting before employees are permitted to work under or between them.”

- Train employees on the hazards associated with working around functioning or malfunctioning dump body systems.OSHA’s construction standard, 29 CFR 1926.21(b)(2), requires that “the employer shall instruct each employee in the recognition and avoidance of unsafe conditions…”

- Contact the original equipment manufacturer to discuss an alternative body prop or other suitable methods to perform maintenace or repair work.

- Engineer safeguard mechanisms/systems such as a “truck bed brace bracket” that will enable a device to be positioned in any fixed position to eliminate or prevent employee exposure to hazardous conditions while maintaining or servicing such equipment.

View the complete article here.

Why is it important to use strong and heavy supports when working under the dump body of a dump truck?

Using strong and heavy supports is crucial to prevent the unintended movement of the dump body, which can lead to serious accidents and injuries to maintenance or servicing personnel.

What should employers do to protect employees from hazards while working under raised dump truck bodies?

Employers should ensure suitable support for elevated equipment, provide training on dump body systems' hazards, and consider alternative body props or engineering safeguard mechanisms/systems to eliminate or prevent exposure to hazardous conditions during maintenance or repair work.